There are several benefits to installing an industrial vacuum system for direct extraction in your machine operation, and that goes for portable machines as well as machines that stand in place. Among the most pertinent of advantages—which spans all types of machine use—is that of efficiency. For example, time spent manually cleaning or dumping dust and chips can instead be directed toward productivity and the machines themselves. Whatever your production, there’s a lot to like about working direct extraction into your process. Stick around for some examples.

Grinders and Shot or Sand Blasters

We’re putting these two into the same section because, typically, your purpose for their use will be quite similar. When preparing concrete surfaces in renovations and builds, you’ll use a grinder or shot blaster to level out the surface and prepare it for polishing or coating. During operation, these machines kick up a lot of crystalline silica, the hazardous particle found in concrete dust which can be dangerous to workers and guests.

Thankfully, there are ways to combat this hazard when operating grinders and shot blasters. Also fortunate – a lot of heavy-duty grinders and blasters will come ready for direct extraction. Simply attach your industrial vacuum to the appropriate port and don’t forget to follow the manufacturer’s directions on both your machine and the vacuum itself.

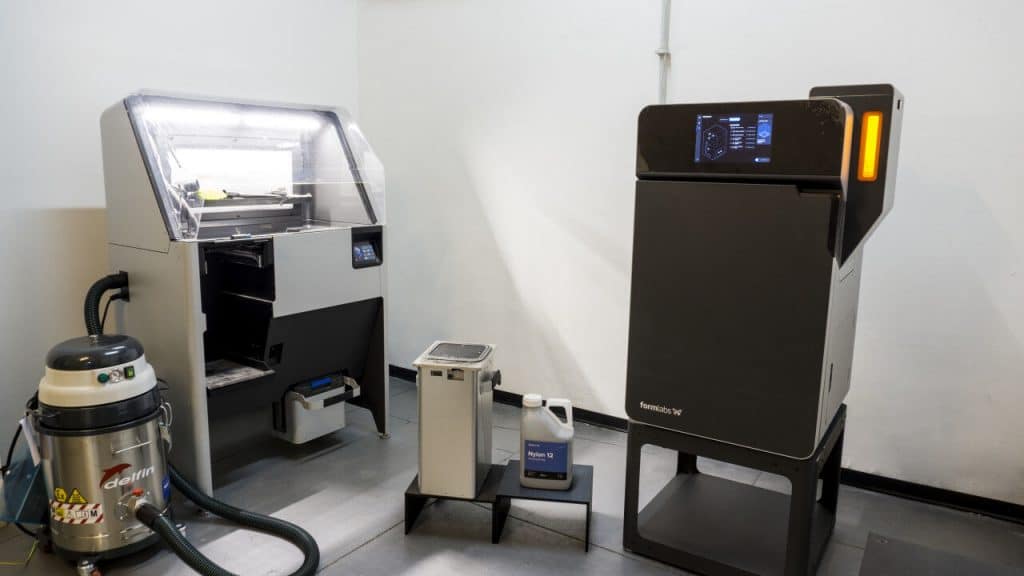

3D Printing and Additive Manufacturing

Every year additive manufacturing technology evolves just a little bit more, and along with the development comes a greater demand for upkeep efficiency. After all, machine owners and investors want to keep machines protected and overhead low in an ever-increasing industry. Direct extraction in 3D printing and manufacturing can help workers avoid cross-contamination, ensure quality production, and save costs by recovering unused, clean powders for future use.

Swiss-Style Lathe Machines

A heavy hitter in the world of CNC subtractive manufacturing, Swiss-style lathe machines are subtractive machines that operate via rotating lathes in a fixed position. Metals and oils can store up very quickly in these machines and, if operators aren’t careful and machines aren’t up-to-date, excess material can compromise the machine’s integrity.

Wet and dry industrial vacuums are the best solution for maintaining continuous, quality production of lathes and similar machines. In fact, the right vacuum can even help operations recycle the oil for reuse, saving on money and even time.

Milling Machines

Quality direct extraction doesn’t stop at Swiss-style machines. Computerized mills are a commonly found machine in CNC subtractive operations as well. And while the purpose and demand are—at times—different from that of a Swiss machine, milling machines will still benefit just as much from direct extraction.

How so? Well, enclosed mills can have material chips and oils flying every which way. Unlike open mills which typically spit the material outward and onto the floor, chips in an enclosed mill ricochet off the walls of the machine and then accumulate within. When the material is removed via industrial vacuum, it saves the operator from extensive upkeep which can add up over time and potentially limit productivity – not to mention the convenience of a quick clean-up.

Direct Extraction and Centralized Vacuum Systems for CNC Manufacturing Operations

For subtractive machine productions that house several machines running on 18–24-hour cycles throughout a plant, you may benefit from a centralized vacuum system (CVS). An adequately installed CVS will have multiple ports for extraction placed throughout the operation, making it easy for workers to simply attach a hose and start the cleaning process without hassle or interruption.

Direct extraction pairs especially well with a CVS because the extraction may be integrated easily into the CVS process. Rather than having a portable industrial vacuum hanging out in your worker’s station, the machine will connect directly to the wall where the chips flow through the installed piping system and into a heavy-duty container.

Custom Vacuum Solutions for Your Industry

At Delfin, we have an extensive catalog of industrial vacuums that are built to serve productions in a variety of ways. We also offer equipment, accessories, and, in some cases, installation assistance.

From portable vacuums certified for regulatory compliance to heavy-duty industrial vacuum cleaners that extract bulk materials, Delfin is able to customize solutions to meet the demands of your operation. Check out our educational resources or connect with us online to learn more.