From everyday medical equipment to life-saving drugs, pharmaceutical advancements help improve the quality of life for millions of people every year. But the technology, production, and machinery required for such advancements come with potential dangers that could be prevented with the right equipment and upkeep.

A Real-Life Example of Pharmaceutical Operations Gone Awry

What kind of danger could a pharmaceutical manufacturing plant possibly be in? Take the West Pharmaceutical Services dust explosion, for example.

In January 2003, an explosion took place that resulted in six fatalities, several injuries, and an abundance of job losses. West Pharmaceutical used this plant to produce various medical products, many of which were made of rubber. The fine plastic powder which was kicked up by the manufacturing of rubber stoppers and syringe plungers had accumulated along the ceiling and ultimately became the fuel for the explosion.

The U.S. Chemical Safety and Hazard Investigation Board (CSB) found that West Pharmaceutical kept to adequate housekeeping and regular dust removal but failed to acknowledge the dust on the ceiling. The dust was ignored to the point where it reached one-quarter to a half-inch in accumulation despite a national fire code of a maximum 1/32 of an inch, leaving one to wonder whether the hazard of combustible dust had even been communicated to the employees.

The CSB then determined that there were a handful of causes that led to the explosion, including “inadequate engineering assessment for combustible powders” and “inadequate communication of dust hazards to workers.” In other words, despite the employees’ attempts at regular upkeep and caution, this disaster was preventable. It leads one to wonder: How much attention to dust accumulation is necessary for pharmaceutical manufacturers to stay safe? Or, for that matter, how does one prevent these disasters?

Preventing Combustible Dust Disasters

First and foremost, to prevent future explosions like that of West Pharmaceutical and others, adhere to your federal and state laws and regulations. Nothing can ramp up your disaster chances like ignoring the very laws put in place to prevent disasters.

Then you will want to ask yourself: Is your manufacturing dust combustible? You might be surprised by what synthetic and organic materials can produce combustible dust. Such materials include:

- Zinc

- Aluminum

- Magnesium

- Xanthan gum

Of course, not all these materials will be found in a pharmaceutical manufacturing plant. But, simply for peace of mind, it can be helpful to know what constitutes combustible dust. Some materials are less obvious than others. In fact, even oat flour, egg whites, and numerous other food sources are on OSHA’s combustible dust list.

Once you have verified the degree of combustibility of your material, consider following these tips for explosion prevention:

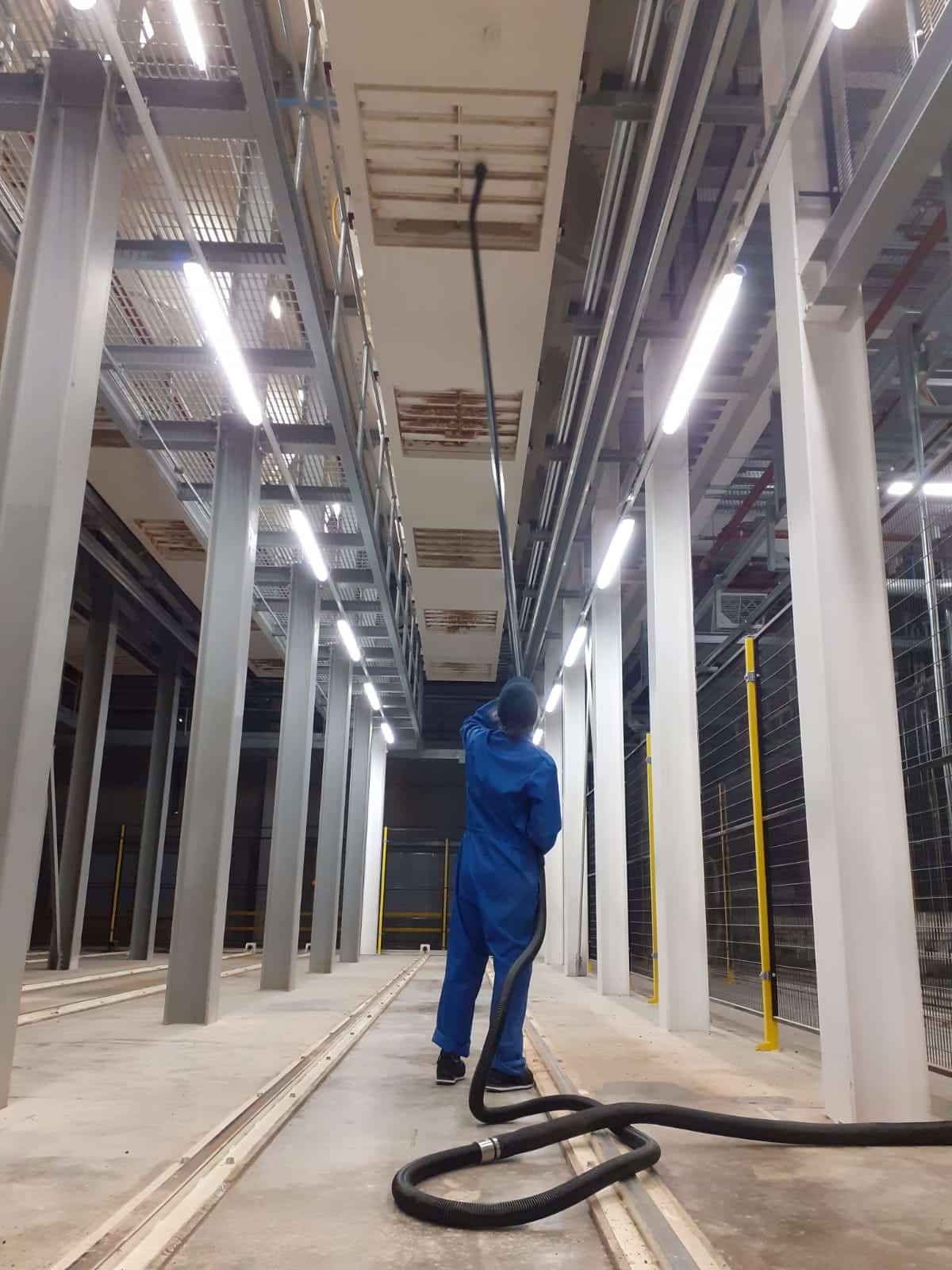

- Have up-to-date ducts and an explosion-proof industrial vacuum system operating smoothly in your plant

- Implement regular housekeeping strategies

- Update your safety handbooks as necessary and keep hazardous dust-related graphics posted around your working areas

- Use working surfaces designed for minimal dust accumulation

- Make sure your electronically powered machines are approved for hazard classification

- Train your employees on the potential hazards of combustible dust

Each industry is unique and will come with its own unique standards for safety and housekeeping – pharmaceutical manufacturing is no exception.

Finding the Right Equipment for the Job

Delfin understands the needs and rigid constraints of the pharmaceutical industry, necessary to guarantee the total safety of the employees and the quality of the end products. That’s why we have designed a specific range of products able to guarantee high levels of hygiene, safety, and productivity. The range is made of specific industrial vacuums, dust containment solutions and pneumatic conveyors to be integrated on production machines. Delfin solutions can cover every step of the production process, from logistics and raw material storage areas to packaging lines. Take the PHARMA 20.18, for example; this model is the perfect ally for direct powder suction from process machines and for general cleaning. If you are looking for a solution for the continuous suction in order to avoid machine downtime and to maintain high productivity stadards for powders up to OEB 3, this is the perfect one. However, if you need to guarantee the safe containment of hazardous powders up to OEB4 and OEB5 (HPAPI), the PHARMA 40.40DC is definitely the way to go. Compact and quiet, this dust containment is equipped with a bag collecting system and made of AISI 316 stainless steel for those parts in direct contact with the product. This model is particularly suitable for connection to tablet pressing machines, shrink wrapping machines and blister machines.

Don’t forget to make sure you convey your products in a safe way! A pneumatic conveyor is surely the perfect solution to load powders into process machinery while completely avoiding any risk of contamination.

Decades of Experience, Ready to Serve You

The right cleaning system can not only help you adhere to regulations, but it can help maintain long-term, around-the-clock productivity. For over 30 years, Delfin Industrial Corporation has provided quality designs and innovations for manufacturers and workers across an array of industries nationwide. We will work with you to find the right equipment and ensure your company meets your industry’s cleaning requirements. Reach out today to learn more about how you can incorporate an industrial vacuum system for combustible dust into your pharmaceutical production line.