Solutions for Avoiding Cross-Contamination

Food, pharmaceutical and chemical companies are faced daily with laws and regulations that require careful and active checks on operational hygiene. One of the most vital topics in this regard is certainly cross-contamination. In order to comply, these operations must take measures to identify points of risk in their production process, monitor them and assess corrective actions where necessary.

At Delfin, we offer a range of solutions to help mitigate the risk of cross-contamination. Some of these solutions include:

✓ Color-coded accessories for vacuuming

✓ Central vacuum systems

✓ Pneumatic conveyors

COLOR CODED ACCESSORIES

Identifying production materials by color is one of the simplest and most recommended procedures for food or pharmaceutical companies that want to avoid cross-contamination.

Color-coded accessories can identify:

✓ A specific food or ingredient

✓ A work area

✓ A special application in the work flow

These can come in the form of attachments for your equipment, bold in color to act as a glaring sign to the eye. When color associations are simple and visually recognizable, it’s much easier to avoid inadvertently combining substances while performing machine maintenance and area upkeep.

Check out our flyer to learn more about color coding and how it can help you mitigate cross-contamination risk.

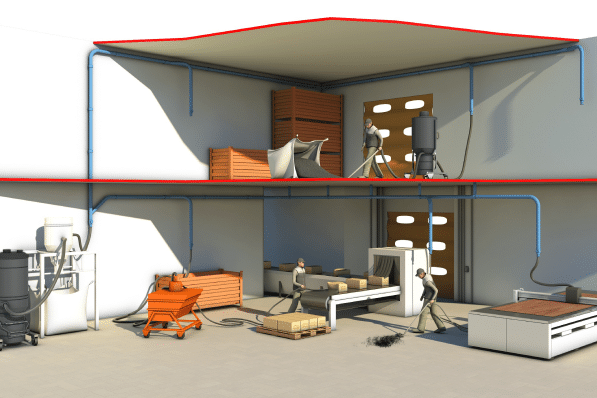

CENTRAL VACUUM SYSTEMS

Delfin’s centralized vacuum systems (CVS) are the easiest and most effective solution for the prevention of substance dispersion and unwanted production are contaminants. Each central vacuum system is tailor-made according to the needs of the operation for hygienic, regulatory, and productivity purposes.

How do centralized vacuum systems help? By installing a system of piping and collection access points throughout your plant, you provide specific areas with extraction channels dedicated to their function.

So, if you have one material on one side of an operation and a potentially conflicting material on the other, the dangers of cross-contamination of these materials—whether via industrial vacuum hose or dust disbursement—are much lower because workers are using separate extraction points.

Other benefits of a CVS may include machine direct extraction opportunities, increased production efficiency, and easy material transfer and disposal.

PNEUMATIC CONVEYORS

The risk of cross-contamination is rarely as high as upon the transfer of material from one station to another. Pneumatic conveyors are the best solution to carry a variety of industry substances, thoroughly eliminating the risk of cross-contamination whether you’re in the pharmaceutical industry, chemical industry, or another contaminant-cautious environment.

What is pneumatic conveyance?

Pneumatic conveyors transport materials like powders and granules via air through an enclosed piping system. Not only can this system help prevent cross-contamination, but the right setup can also improve operational efficiency. Our pneumatic conveyor systems may be installed according to the bounds of your operation as they are modular and may be easily customized.

Reach Out to Learn More About Our Cross-Contamination Solutions

At Delfin, we have an extensive catalog of industrial vacuum cleaners and dust collection systems that meet a wide range of industry demands. Whether you’re looking to improve your production’s upkeep process or you have concerns about meeting federal compliance, we have the resources and knowledge necessary to connect you with the right solution.

Call today or connect with us online to get started.