Industrial Vacuum Solutions for Chemical Processing

Rarely is cleanliness more important to an operation than those with chemical processing at the center of their business. As managers and owners know, chemical processing requires a hygienic and careful approach or the pitfalls could be disastrous. During production, three dust-related factors can compromise the final result:

✓ The risk of cross-contamination

✓ The danger of inhalation of fine and dangerous dust

✓ Combustible dust suspended in the air

Contamination may occur in several forms:

✓ Physical contamination; fragments and dust from compression machinery

✓ Chemical contamination; steam, humidity, molecules

✓ Biological contamination; bacteria, fungi, viruses

Regardless of industry, fine dust can pose a danger to just about everyone in its immediate environment. As it relates to chemical processing, there is a wide range of dust types in pharmaceutical, food and agriculture and other operations that are explosive.

There is no greater need than the need to protect the operator and other workers from this danger, and that’s where effective fine dust collectors like industrial vacuums come into play. Our certified vacuums and filters have the capability to collect and contain even the finest of dust.

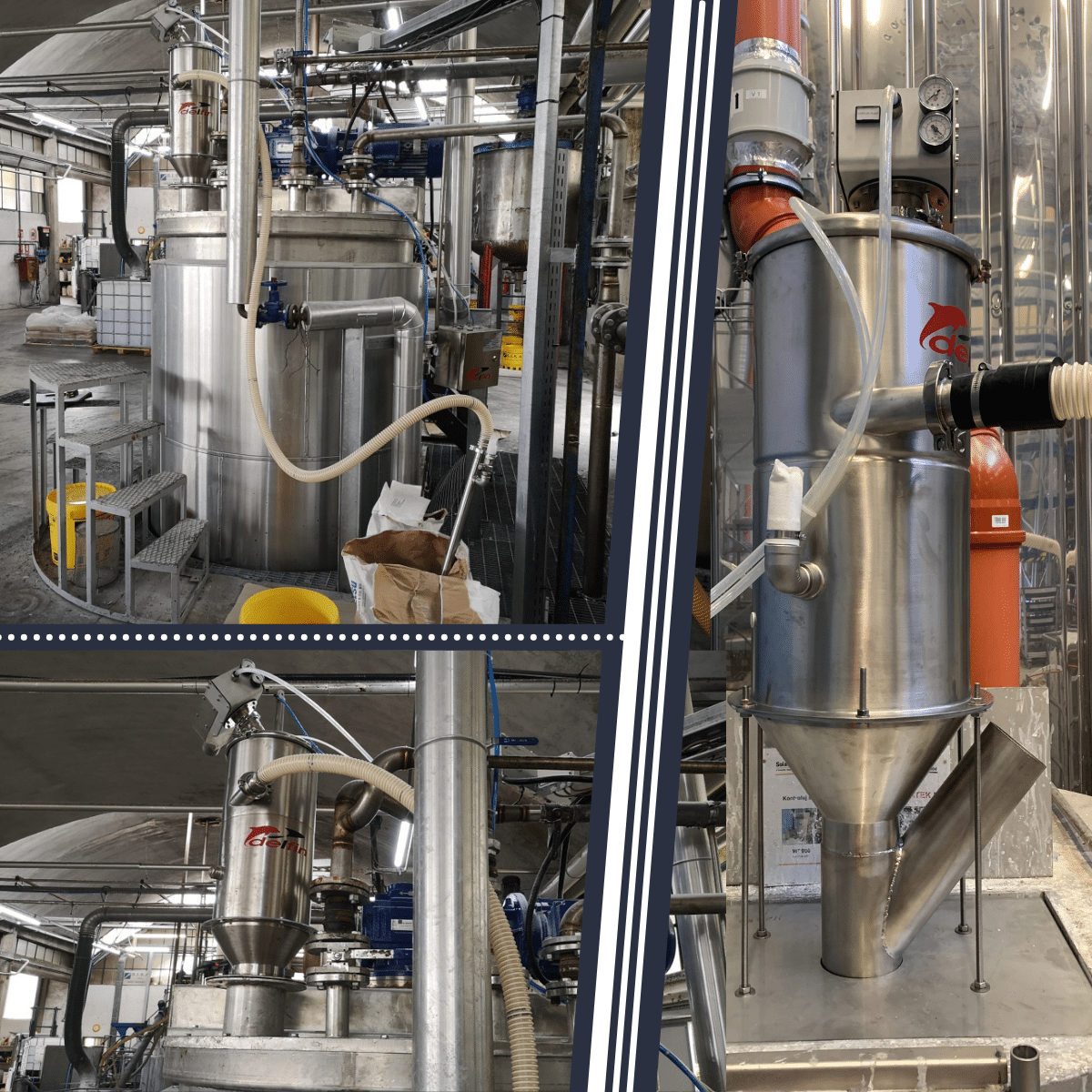

Delfin offers a complete range to meet every need for cleanliness, efficiency and safety.

✓ NRTL and ATEX certified vacuum cleaners for safe and certified vacuuming for companies and individual operators in contact with dust

✓ Pneumatic Conveyor for safe dust handling, avoiding any contamination with other products or substances

✓ HEPA filtration to ensure absolute filtration, retaining all the hazardous dusts inside the vacuum

✓ Vacuum cleaners in stainless steel with smooth surfaces, designed to prevent the accumulation of dust, and to make it easy and safe for operators to clean and maintain

For industries where cross-contamination is not only a danger to product quality but is a matter of consumer safety and regulation compliance, a pneumatic conveyor system is a must. The last thing chemical processing plants need is cross-contamination. Conveyors simplify the material transport process and lead to a more hygienic, safe environment for everyone.

Benefits of pneumatic conveyance include:

✓ Simple maintenance and low wear

✓ Prevent leakage and contamination of products

✓ May be installed with other machinery in the transport line

✓ Modular piping makes for an adaptable setup perfect for a variety of different spaces

At Delfin, we not only offer a full spectrum of dust extraction products, but we also make a point to partner with manufacturers from initial steps to dust solution completion. Whether your operation requires a centralized vacuum system, pneumatic conveyance, or other collection solutions like direct extraction, we’re here to help.

Learn more by checking out our educational resources. Looking to speak to someone? Give us a call or connect online today.