The pharmaceutical industry plays a pivotal role in guaranteeing people’s wellbeing all over the world. This means developing. producing and distributing medications that improve and save lives. To do so, it is fundamental to ensure the release of top-quality, impeccable products, free from any cross-contamination.

In order to guarantee this quality, it is important to keep an eye on those powders and dusts that are generated during the different production phases, making sure that they are not spread into the environment, mixed to other excipients or touched/inhaled by operators. In fact, some of these powders are considered toxic or even highly toxic.

THE DIFFERENT PHASES OF THE PHARMACEUTICAL PRODUCTION PROCESS

This dynamic sector encompasses a vast array of processes and technologies, all geared towards the creation of pharmaceutical products. Let’s take a closer look at these phases and the potential hazards associated with some of them.

Production Processes

The production of pharmaceuticals involves a series of carefully controlled and regulated processes to ensure the safety, efficiency, and quality of the final products. These processes typically include drug discovery, pre-clinical development, clinical trials, regulatory approval, and finally, manufacturing and distribution.

Manufacturing processes in the pharmaceutical industry are complex and require advanced machines to achieve precision and consistency. Some of the key machines used in the production process include:

- Mixers and Blenders: These machines are essential for homogenizing the active pharmaceutical ingredients (APIs) with various excipients, ensuring a uniform blend.

- Granulators: Used to create granules from the blended ingredients, facilitating the compression of tablets or the filling of capsules.

- Tablet Presses and Capsule Fillers: These machines are employed for the actual creation of tablets or the filling of capsules with the pharmaceutical formula.

- Coating Machines: Used to apply coatings to tablets or capsules, enhancing stability, appearance, and sometimes controlling the release of the active ingredient.

- Packaging Machines: Involved in the final stage of production, packaging machines ensure the proper and safe delivery of pharmaceutical products to end-users by wrapping them in closed, sealed packages.

DUST PRODUCTION AND HAZARDS

During the manufacturing process, the generation of dust can be a significant concern, particularly with tablet presses and capsule filling machines. Dust may contain active pharmaceutical ingredients, excipients, or other particles that pose potential health risks to workers and may compromise product quality. This is especially true for potent compounds with low occupational exposure limits.

The phases where dust is commonly produced include the handling of raw materials, blending, granulation, milling, and tablet compression. Inhalation of pharmaceutical dust can lead to respiratory issues, skin irritation, or other health problems. Additionally, cross-contamination between different drug products is a concern, as it may compromise the purity of the product.

To mitigate these risks, pharmaceutical manufacturers employ strict containment measures, including the use of isolators, closed-system transfer devices, and dust collection systems. These precautions help protect both the workers and the integrity of the pharmaceutical products.

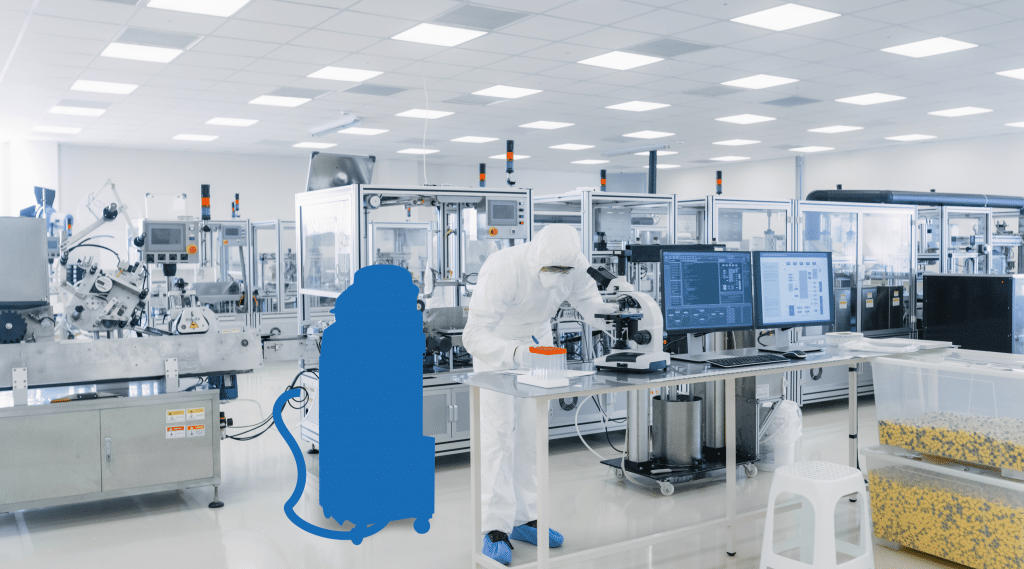

THE ADVANTAGES AND BENEFITS OF USING DELFIN INDUSTRIAL VACUUMS FOR PHARMA INDUSTRY AND PHARMA DUST CONTAINMENT SYSTEMS

Delfin’s top priorities have always been to ensure operators’ safety, avoid cross-contamination and guarantee production efficiency. That’s why we have used our 30 years of experience in the field of industrial vacuuming to design a specific range of vacuum systems, notably for the pharmaceutical industry. We offer our expertise and innovation through high potent pharma dust control.

- Wide and diverse range of products to meet the specific needs and challenges of each phase of the production line.

- Dust filtration and pharma dust containment systems, among the best on the market; compact, highly performing, and competitive.

- Cutting-edge systems to avoid any contact between the operator and the toxic dust (BIBO, bag-in bag-out filter replacement; API/HPAPI containment solutions – OEB3-5).

- Individually tested HEPA absolute filters to guarantee intact product and features.

- Cyclonic systems (up to 98% efficiency) for top filtration in a compact solution which doesn’t require any replacement.

- Customizable control panels for your specific production line needs.

- Mobile and fixed solutions for general and specific cleaning, in full compliance with GMP standards.

- Avoid any downtime to increase productivity.

- Modular solutions for customized combinations and positioning, even outside the production area. Optimized space; noise and heat emissions control.

- Innovative pneumatic conveying solutions for the loading of products on production machines.

DELFIN INDUSTRIAL: A COMPLETE RANGE OF SOLUTIONS

The wide range of Delfin Industrial solutions covers all stages of the production process and even more. Starting from the logistics and the raw material storage areas, the pre-production areas, production areas, cleanrooms and packaging lines, our portable and fixed vacuum solutions have got it covered.

-

INDUSTRIAL VACUUM CLEANERS FOR PHARMACEUTICAL POWDERS OEB1-2

These models can easily handle those accidental spills of very low toxic/low toxic powders. Solutions like large collection capacity portable vacuums and central solutions with fixed piping will easily do the job. Moreover, thanks to their extraction arms, dust collectors can capture airborne dust to avoid its spread into the environment and the operators’ exposure to the product. The loading and conveying of raw materials is easily and safely carried out by a closed, completely sterile pneumatic conveyor.

-

INDUSTRIAL VACUUM CLEANERS FOR PHARMACEUTICAL POWDERS OEB3

Medium toxic powders can be safely handled by integrated solutions directly on production lines, so as to get rid of powders while reducing maintenance operations.

-

INDUSTRIAL VACUUM CLEANERS FOR PHARMACEUTICAL POWDERS OEB4 AND OEB5

When the powder is highly or very highly toxic, Delfin Industrial’s process-integrated models can guarantee top quality products and total safety. In fact, these vacuums are completely closed, with a sealed collection system that guarantees full protection from inhalation or spread into the environment. Also, these vacuums are a must-have to prevent downtimes due to maintenance. In fact, thanks to the so called “wash-in-place” cleaning system, the vacuum doesn’t need to be moved out of the production area, consequently preventing all those onerous costs (sometimes, even thousands of dollars!) caused by moving the machines to different areas aimed at carrying out the necessary cleaning operations.

At some stages, the removal of dust or powders is not necessarily from a phase of the production line directly involving exposure to dust. However, these phases require some thorough cleaning too. Phases like pharmaceutical cleanroom cleaning, covered by our autoclavable models for dry or wet dry vacuum needs. In this case, safety is guaranteed by the ULPA filters installed inside the vacuums. These are autoclavable solutions, safe for ISO4 or higher needs.

Another example is the removal of packaging waste like scraps and trimmings (cardboard, plastic film and so on), directly from the source.

If you want more information on the specific products suitable for every phase of the production line and discover more about the different active ingredients, visit our Pharma solutions section and contact us today: our team of experts is looking forward to talking to you! Last but not least, we would like to share with you our in-depth analysis on dust suppression and containment solutions for pharmaceutical dust. Enjoy your reading!”