A key feature of a high-quality vacuum system is its ability to retain the vacuumed waste while preventing its reintroduction into the working environment. In this regard, industrial vacuum cleaner filters play an essential role. In fact, they provide high standards of efficiency, work environment safety and cleanliness. Thanks to highly efficient filtration systems, Delfin industrial vacuum cleaners ensure the reinsertion of filtered and clean air into the work environment. This way, the risk of inhalation of toxic substances by workers is minimized. At the same time, industrial vacuum filters are a key ally in avoiding cross-contamination and explosion risks.

A FILTER FOR EVERY APPLICATION

Delfin Industrial offers various industrial vacuum filters, specifically for the needs of every application. Every sector has special requirements and challenges; choosing the right filter is fundamental. That’s why every filter has distinct granulometry and features, so that they can vacuum particles of any size.

- Class L (Low) filters can retain more than 99% of dust particles smaller than 3 microns. They are typically used when dust poses a modest risk to employees’ health, such as general cleaning.

- Class M (Medium) filters can retain 99.9% of dust particles less than 1 micron in size. They are typically used in areas where dust poses a medium threat to worker health, such as the food and plastic sectors.

- Class H (High) filters: these are paired with a star class M filter to achieve a 99.99% efficiency for dust particles smaller than 0.18 Micron. Class H filters are ideal when dealing with hazardous dust in industries such as pharmaceuticals and floor preparation.

COMBINE FILTERS FOR HIGHER SAFETY

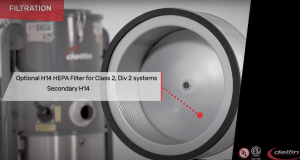

To ensure the maximum level of filtration, Delfin industrial vacuum systems are generally equipped with a combination of two filters – primary and secondary. The goal of the primary filter is to trap the greatest number of vacuumed particles, thus protecting the motor from malfunctions, wear, and downtime. The secondary filter is the absolute filter with HEPA certification. The industrial HEPA vacuum filter provides excellent dust retention. It stops any other residues that couldn’t be captured by the first filter, before they reach the motorhead and cause issues.

Depending on the specific applications and industrial sectors, the needs to be satisfied change significantly and, with them, the types of filters to be used. Below, a brief overview of industrial vacuum filters used in major industries.

INDUSTRIAL VACUUM FILTERS FOR FOOD INDUSTRY

In the food industries, high-performance filtration systems are essential to address two major problems. The first one is cross-contamination threatening the preservation of the end-product quality. The second one is explosion risk due to the presence of conductive or highly flammable raw materials. Delfin industrial vacuum cleaners are therefore equipped with polyester antistatic filters. These filters have a steel wire mesh that creates continuity with the vacuum cleaner. Its goal is to prevent the accumulation of electrostatic charge and therefore sparks, one of the main ignition sources. For environments like bakeries or ovens, where dust extraction occurs at high temperatures, Delfin Industrial offers industrial vacuum solutions equipped with NOMEX filters, capable of withstanding temperatures – up to 356°F (180 ºC).

INDUSTRIAL VACUUM FILTERS FOR PHARMACEUTICAL INDUSTRY

In the pharmaceutical and chemical industries, the production process involves high standards of hygiene and safety to ensure a secure, compliant, and high-quality end-product.

These industries simultaneously deal with highly hazard and toxic substances; the menace of cross-contamination due to external agents, and the risk of inhalation of toxic substances by operators. Therefore, prevention is not a joke. That’s why Delfin has designed the new dust containment range to specifically solve these problems. This range is provided with different levels of filtration, including absolute HEPA filters with progressive efficiency, among which ULPA filters (especially for cleanrooms with the Labcontrol range).

INDUSTRIAL VACUUM FILTERS FOR MECHANICAL MANUFACTURING

The mechanical industries are focused on ensuring the maintenance and cleaning of machines such as CNC, lathes and cutters through the vacuuming and separation of oils and chips. Lubricating oils used during the mechanical processing can be filtered and put back into the production process, increasing efficiency and reducing waste. For this reason, Delfin Industrial vacuum cleaners for the mechanical sector are equipped with PPL bag filter, polypropylene mesh to filter liquids by separating them from metal chips and other coarse residues. Available for filtration up to 100 microns.

INDUSTRIAL VACUUM FILTERS FOR 3D PRINTING

3D printing is another sector dealing with potentially explosive powders. Delfin Industrial offers a specific range of inert solutions including a PPL filter. The vacuums of this range are equipped with a canister that makes the powders unharmful by means of an inert oil, thus preventing any risk of explosion. Three other fiber filters retain the mist generated by the vacuuming.

In case of non-reactive powders, Delfin Industrial provides antistatic class M filters in its industrial vacuum cleaners. These can be integrated with industrial vacuum HEPA filters to increase the filtration standard and guarantee the release of clean air into the environment.

Delfin’s top priority is to meet your everyday needs. This is why our team of experts is always engaged in the study and design of new industrial vacuum solutions specifically aimed to solve each industries’ issues. Contact us to learn more about Delfin industrial vacuum cleaner filters options and discover which is more suitable for your business and industrial applications.